From Design to Installation: How a Custom WM System Ramp is Born

Where craftsmanship meets technology to make every space accessible

There is a precise moment when engineering meets necessity, and from that encounter, something is born that improves peoples’ lives. In the case of WM System, that moment occurs every time a custom ramp takes shape.

Behind every installation—whether it’s a small private entrance or a large public building—lies a journey made of listening, designing, testing, and precision. It is an entirely Italian supply chain, where every detail is studied and built in-house, in the heart of Reggio Emilia.

Here is how a WM System ramp is created, step by step: a journey into the method of a company that for over thirty years has been synonymous with mobility, safety, and “Made in Italy” accessibility.

- Listening: The Starting Point of Every Project

Everything begins with a need in real life. It could be a municipality in need to make a town hall accessible, a company looking to improve safety in its warehouses, or a family wanting to overcome a barrier at home.

The first step is always listening: understanding who will use the ramp, how often, and in what context. In this stage, the WM System team’s experience becomes decisive.

“Every ramp is an answer to a specific story,” explains Gerardo De Micco, Head of the Architectural Barriers Department. “We don’t design for categories; we design for people. The difference between a standard product and a WM System ramp lies entirely in the ability to adapt.”

The technical survey—whether physical or virtual—is used to take measurements and evaluate slopes, assessing space, flooring, and every detail that might affect the user experience.

- Listening: The Starting Point of Every Project

Everything begins with a need in real life. It could be a municipality in need to make a town hall accessible, a company looking to improve safety in its warehouses, or a family wanting to overcome a barrier at home.

The first step is always listening: understanding who will use the ramp, how often, and in what context. In this stage, the WM System team’s experience becomes decisive.

“Every ramp is an answer to a specific story,” explains Gerardo De Micco, Head of the Architectural Barriers Department. “We don’t design for categories; we design for people. The difference between a standard product and a WM System ramp lies entirely in the ability to adapt.”

The technical survey—whether physical or virtual—is used to take measurements and evaluate slopes, assessing space, flooring, and every detail that might affect the user experience.

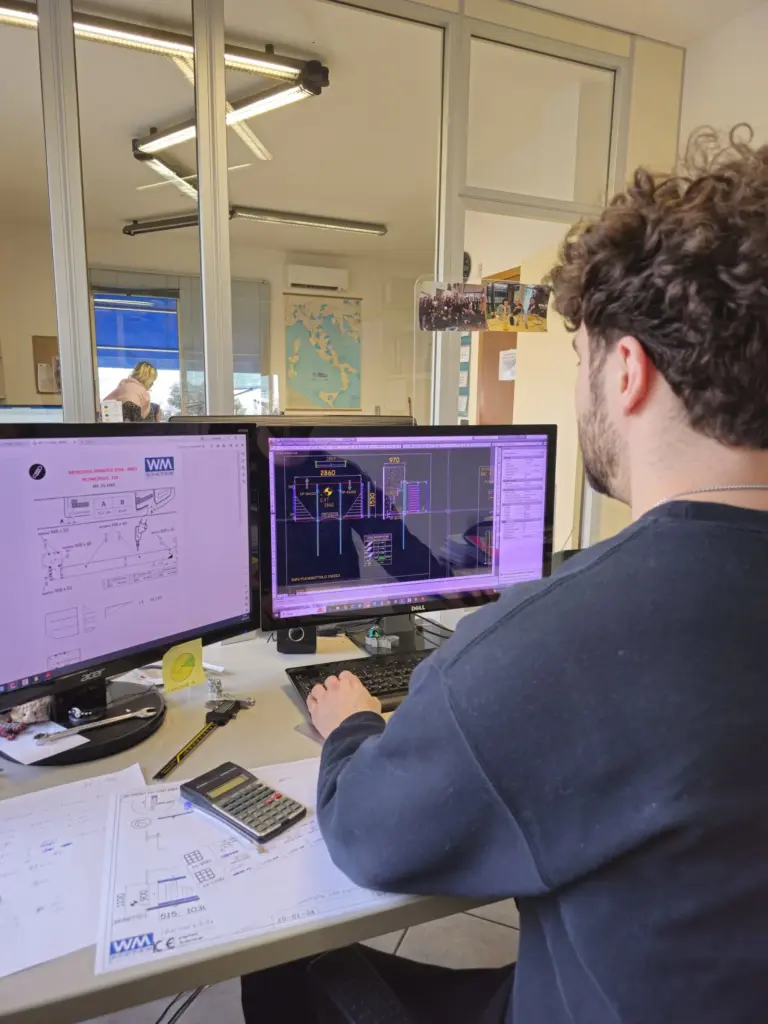

- Design: Where Precision Meets Regulations

Once the data is collected, the technical department takes over. Here, 3D modeling software and CAD design allow for the creation of a detailed project based on national and international regulations.

In Italy, the main references are Ministerial Decree 236/1989 and Presidential Decree 503/1996, which regulate slopes, minimum widths, landings, and safety features. Every WM System model is designed to guarantee a maximum slope of 8% for fixed ramps, featuring non-slip surfaces and lateral safety edges where required.

“Regulations are our foundation, but we don’t stop there,” adds Simone Ferraresi, Technical Designer. “A good project must also be harmonious and respectful of the environment. For us, a ramp is part of the architecture, not a meaningless addition.”

The result of this stage is a visual and functional proposal: a realistic render or mockup that shows the client exactly how the ramp will look once installed. This allows potential issues to be prevented and makes the process transparent, even for non-experts.

- Production: The Beating Heart of WM System Quality

From design to reality, the transition takes place in the production department in Rolo (RE), where technology and craftsmanship coexist.

WM System ramps are made of non-slip anodized aluminum alloy—a lightweight, corrosion-resistant material suitable even for outdoor environments. Latest generation laser cutting machines, connected to an automated 4.0 warehouse, work autonomously even at night to optimize production times.

However, automation does not replace human overseeing: every piece is finished and assembled by hand to ensure millimetrical precision and impeccable finishes.

“Two ramps are never identical,” says Ilaria Ghidoni, Italy Sales Manager. “The measurements, the context, and the function change. What never changes is our attention to detail and the quality of the materials.”

Each ramp undergoes internal quality control, including load tests and weld inspections, before being packed and shipped.

- Installation: The Final Step Toward Accessibility

Installation is the most visible phase—and the most rewarding. During this stage, WM System technicians or authorized dealers intervene on-site to mount the ramp, verify alignments, secure the elements, and test stability.

Whether it is a fixed access ramp for a public building or a mobile ramp for commercial vehicles, the installation is designed to be fast, safe, and clean. Most installations are completed in less than a day.

After installation, customers receive a complete technical sheet with instructions for use, maintenance, and cleaning—a small gesture that makes a big difference in terms of safety and durability over time.

- From a Single Project to a Collective Vision

Every ramp installed is more than just a product sold: it is a piece of a larger project to make mobility and accessibility part of everyday culture.

Today, WM System ramps can be found in schools, theaters, hospitals, airports, logistics companies, international expos, and private homes. From the Basilica of Aquileia to the accessible beaches of Eraclea, every context tells a different story of making possible what was previously a limit.

“True innovation is not the technology, but the impact it generates,” concludes Gerardo De Micco. “Every ramp installed is a story of access, inclusion, and freedom. That is why we continue to design every day with the same passion.”

From the first contact to the final assembly, every WM System ramp is the result of an entirely Italian supply chain that combines engineering, experience, and human connection. This is the key to the success of a brand that for over 30 years has been making the world of work and public spaces more accessible, safer, and more efficient.

When accessibility is done well, you don’t notice it: you live it, you walk through it, you take it for granted.

📩 Want to discover how the perfect ramp for your space? 👉 Contact the WM System experts today.

4. Il montaggio: l’ultimo passo verso l’accessibilità

L’installazione è la fase più visibile — e anche la più gratificante.

In questa fase, i tecnici WM System o i rivenditori autorizzati intervengono sul posto per montare la rampa, verificarne l’allineamento, fissare gli elementi e testarne la stabilità.

Che si tratti di una rampa fissa d’accesso per un edificio pubblico o di una rampa mobile per veicoli commerciali, il montaggio è pensato per essere rapido, sicuro e pulito.

La maggior parte delle installazioni avviene in meno di una giornata.

Dopo il montaggio, i clienti ricevono una scheda tecnica completa con istruzioni per l’uso, manutenzione e pulizia.

Un piccolo gesto che fa la differenza in termini di sicurezza e durata nel tempo.

5. Dal singolo progetto a una visione collettiva

Ogni rampa installata è più di un prodotto venduto: è un pezzo di un progetto più grande, quello di rendere la mobilità e l’accessibilità parte della cultura quotidiana.

Le rampe WM System oggi sono presenti in scuole, teatri, ospedali, aeroporti, aziende logistiche, fiere internazionali e case private.

Dalla Basilica di Aquileia alle spiagge accessibili di Eraclea, ogni contesto racconta un modo diverso di rendere possibile ciò che prima era un limite.

“La vera innovazione non è la tecnologia, ma l’impatto che genera,”

conclude Gerardo De Micco.

“Ogni rampa installata è una storia di accesso, di inclusione e di libertà.

Ed è per questo che continuiamo a progettare, ogni giorno, con la stessa passione.”

Dal primo contatto al montaggio finale, ogni rampa WM System è frutto di una filiera interamente italiana che unisce ingegneria, esperienza e ascolto umano.

È questa la chiave del successo di un marchio che da oltre 30 anni rende il mondo del lavoro e degli spazi pubblici più accessibile, più sicuro, più efficiente.

Perché l’accessibilità, quando è fatta bene, non si nota:

si vive, si attraversa, si dà per scontata.

📩 Vuoi scoprire come nasce la rampa perfetta per il tuo spazio?

👉 Contatta gli esperti WM System